5S Methodology

Summary: 5S is Nippon concept for workplace keeping; the name derives from five words that in Japanese start with letter “S”. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work. The original concept of 5S has been twisted and partially lost: at first its real meaning was referred to five “good qualities” of a virtuous person or company, the transliteration or translation altered them as step of a process, and for this reason strongly within the framework of standard ISO.

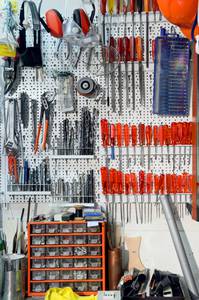

Target of the standard: The list describes how to organize a workplace for efficiency and effectiveness by identifying and storing the items used, maintaining the area and useful items, and sustaining the new order, passing through 5 steps:

- Seiri – Sorting, remove what is not needed and keep what is needed.

- Seiton – Straightening, arranging properly tools, parts and instructions in such a way that the most frequently used items are the easiest and quickest to locate.

- Seiso – Sweeping, keep things clean and polished; no trash or dirt in the workplace.

- Seiketsu – Standardizing, maintain cleanliness after cleaning – perpetual cleaning.

- Shitsuke – Sustaining, maintain and review standards and do not allow a gradual decline back to the old ways.

For whom? : For every company, especially for industrial, installing, automotive sectors.

Benefits: We MTIC InterCert India Private Limited got knowledge and qualified personnel to verify the efficient and effective application of 5S methodology, providing to companies:

- a prestigious attestation,

- successful and continuous improvement,

- collective collaboration,

- sense of belonging,

- participation for one goal.